Apparecchiatura di saldatura CNC automatica ad angolo tondo di alta precisione

Panoramica del prodotto

1. Precisione e nucleo di automazioneQuesta apparecchiatura sfrutta la tecnologia CNC (Computer Numerical Control), consentendo la saldatura ad angolo tondo di alta precisione con un margine di errore inferiore a 0,1 mm. Il suo funzionamento completamente automatico, dal posizionamento del pezzo alla saldatura completa, elimina gli errori manuali, garantendo una qualità di saldatura costante tra i lotti, ideale per i prodotti che richiedono un'accuratezza dimensionale rigorosa.

2. Vantaggi della saldatura ad angolo tondo

Specializzata in giunti ad angolo tondo, gestisce senza problemi saldature curve su componenti metallici (ad esempio, lavelli in acciaio inossidabile, armadietti in lamiera). Il processo di saldatura riduce al minimo la distorsione termica, mantenendo intatta la forma originale del pezzo, mentre le saldature arrotondate migliorano la resistenza strutturale e l'estetica, evitando spigoli vivi che potrebbero compromettere la sicurezza o l'aspetto.

3. Efficienza e versatilità

Supporta la regolazione rapida dei parametri tramite un'interfaccia CNC intuitiva, adattandosi a diversi spessori di materiale (0,5–5 mm) e raggi d'angolo tondi (R2–R20 mm). Rispetto alla saldatura manuale, aumenta la produttività del 30–50%, adatta a settori come la produzione di articoli per la cucina, ferramenta per mobili e componenti automobilistici.

Caratteristica principale

1. Saldatura a controllo numerico di alta precisione: Attraverso il sistema di controllo numerico per pianificare con precisione la traiettoria di saldatura, per garantire che la saldatura arrotondata sia uniforme, bella, con una buona formazione del cordone di saldatura, senza saldatura virtuale, fenomeno di perdita di saldatura, precisione di saldatura fino al millimetro.

2. Procedure di saldatura personalizzate: In base al diverso materiale in acciaio inossidabile, allo spessore e alle dimensioni dello smusso, gli utenti possono impostare i propri parametri e percorsi di saldatura per soddisfare le diverse esigenze di saldatura e ottenere una produzione personalizzata personalizzata.

3. Alimentazione automatica del filo e controllo a corrente costante: dotato di un efficiente sistema di alimentazione automatica del filo per garantire una trasmissione continua e stabile del filo; La tecnologia di controllo a corrente costante garantisce una corrente di saldatura stabile, un processo di saldatura stabile e una qualità di saldatura costante.

4. Monitoraggio intelligente e diagnosi dei guasti: monitoraggio in tempo reale del processo di saldatura di corrente, tensione, temperatura e altri parametri, una volta anomalo, il sistema si allarma e si arresta automaticamente, fornendo al contempo informazioni di diagnosi dei guasti per un'indagine e una riparazione rapide.

scenario applicativo

1. Produzione di mobili in acciaio inossidabile: utilizzato per realizzare sedie, tavoli, armadietti e altri mobili in acciaio inossidabile con saldatura ad angolo tondo, migliorare la qualità dell'aspetto e la stabilità strutturale del prodotto, per soddisfare il mercato dei mobili di fascia alta sui severi requisiti del processo di saldatura.

2. Produzione di attrezzature per cucina e bagno: Prestazioni eccellenti nella saldatura ad angolo tondo di lavelli in acciaio inossidabile, scocca del fornello a gas, cappa aspirante e altre attrezzature per cucina e bagno, per garantire la tenuta e la durata dell'attrezzatura, per garantire la qualità del prodotto e la durata.

3. Ingegneria delle decorazioni: Adatto per ringhiere in acciaio inossidabile, corrimano, linee decorative e altre saldature ad angolo tondo, per fornire una soluzione di saldatura bella e solida per l'ingegneria delle decorazioni architettoniche, migliorare l'effetto decorativo complessivo.

4. Lavorazione e produzione: Svolge un ruolo importante nella saldatura ad angolo tondo di parti strutturali in acciaio inossidabile come parti meccaniche e telai metallici, aiutando le aziende di produzione di macchinari a migliorare l'efficienza produttiva e la qualità dei prodotti e a migliorare la competitività del mercato.

Parametro del prodotto

| Dimensioni del corpo |

1400x1100x2000 |

| Voltaggio |

220V |

| Potenza |

400W |

| Il modo di bloccaggio |

pnuema-lock |

| Metodo di controllo |

Sistema CNC Starart |

| Pressione dell'aria compressa |

0,2-1,0 Mpa |

| Spazio occupato |

1400x1100mm |

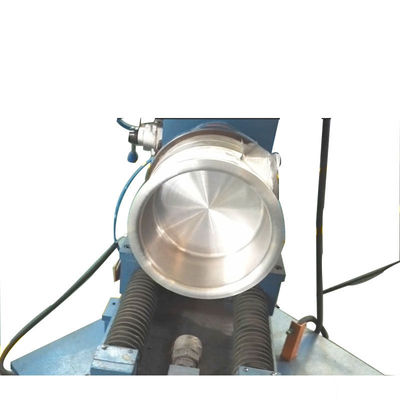

Foto del prodotto

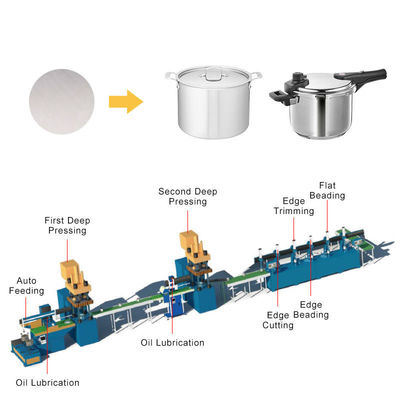

Processo personalizzato

• Personalizzazione su richiesta: specificare soluzioni di progettazione personalizzate per i clienti e fornire ai clienti delle scelte.

• Determinare il programma personalizzato: In base alle esigenze dei clienti, il nostro team di progettazione svilupperà un programma personalizzato, inclusi i parametri del processo di saldatura, la configurazione dell'apparecchiatura, ecc.

• Consegna dell'ordine : Il cliente ordina e paga in base al piano personalizzato, in modo che il lavoro proceda senza intoppi.

• Organizzare la produzione: Dopo aver confermato il piano e il preventivo, entrare nella fase di produzione. Seguiremo rigorosamente il programma personalizzato per la produzione, per garantire che l'apparecchiatura soddisfi i requisiti del cliente. Al termine della produzione, viene eseguito un rigoroso controllo di qualità per garantire prestazioni stabili e affidabili dell'apparecchiatura.

• Servizio post-vendita: Consegnare l'apparecchiatura al cliente in conformità con i tempi concordati e fornire servizi di supporto post-vendita.

La nostra azienda opera da molti anni, con una ricca esperienza di produzione, un servizio completo per farti stare tranquillo dopo la vendita, in attesa della tua chiamata, la nostra azienda ti servirà con tutto il cuore.

Vantaggio aziendale

Foshan Star Power Technology Co., LTD. ha molti anni di esperienza e un team tecnico professionale nel campo delle apparecchiature di saldatura e si impegna a fornire ai clienti prodotti e servizi di qualità. La nostra saldatrice a filetto ha superato rigorosi controlli di qualità e verifiche di mercato e gode di una buona reputazione e soddisfazione dei clienti. E la nostra azienda ha una catena di produzione di lavelli completa e le sue macchine, scegli la saldatrice ad angolo della nostra azienda, significa scegliere una soluzione di saldatura efficiente, stabile e affidabile per aiutare lo sviluppo del tuo business.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!